The New Mandate in Beauty Packaging

The global beauty and personal care industry is undergoing a profound transformation. As consumers become increasingly conscious of their environmental footprint, the demand for sustainable cosmetic packaging has skyrocketed. Brands are now measured not just by the quality of their formulations, but by the integrity of their supply chain and the circularity of their packaging materials.

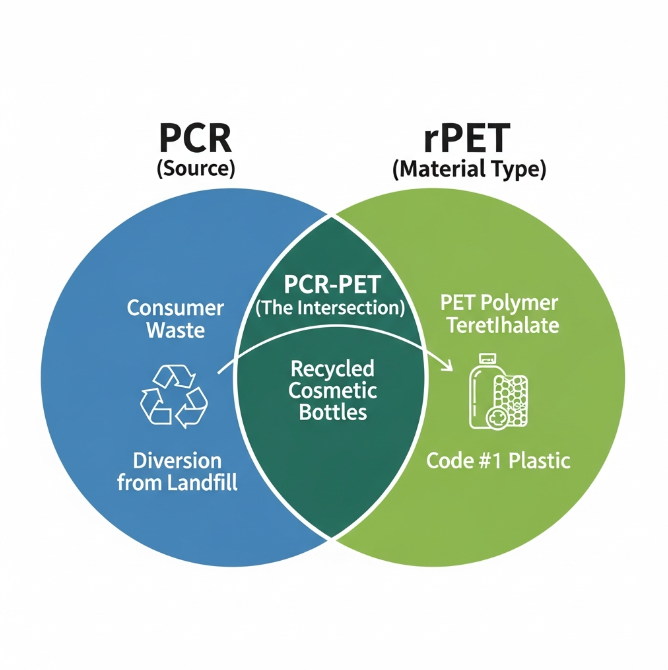

In this movement, two acronyms dominate the conversation regarding recycled plastic bottles: PCR (Post-Consumer Recycled) and rPET (Recycled Polyethylene Terephthalate). While these terms are often used interchangeably in marketing, they represent fundamentally different concepts—one relates to the source of the material, and the other refers to the type of plastic.

This comprehensive guide aims to demystify the relationship between PCR and rPET, providing cosmetic brands seeking to create an Environmental Cosmetic Bottle and environmentally conscious consumers with the clarity needed to make informed, impactful decisions. We will define both terms, dissect their core differences, analyze their performance, and explore why choosing the right material matters for your brand's sustainability story.

Decoding Sustainable Packaging – The Landscape

Before diving into PCR and rPET, it’s essential to understand the three primary categories of sustainable packaging that dominate the beauty market. As discussed in our content analysis, not all sustainable solutions require the same consumer effort.

Recyclable Packaging

A product is recyclable if its material can be processed and reused as raw material. The benefit of this packaging type is entirely dependent on the consumer's action—they must know where and how to dispose of it properly, and local recycling infrastructure must support it. Many rPET Cosmetic Bottle caps and components, while potentially recyclable, depend on proper sorting. This inherent reliance on consumer behavior and inconsistent municipal services often creates a "gap" between packaging that can be recycled and packaging that is recycled. The failure to adequately address this gap highlights why closing the loop with PCR material is often a more reliable immediate sustainability gain for brands.

Compostable Packaging

Compostable packaging is designed to break down into non-toxic elements at the same rate as cellulose (paper) in a composting environment. The challenge here is the infrastructure; many consumers lack access to industrial composting facilities required for most compostable plastics. Misplaced compostable materials often contaminate conventional recycling streams, making this solution complex for widespread cosmetic use unless proper collection and industrial composting facilities are readily available to the end-user. Furthermore, the conditions required for effective composting are rarely met in a typical home composting pile.

Post-Consumer Recycled (PCR) Packaging

PCR packaging offers a powerful solution by closing the loop before the product even leaves the shelf. It is material that has already completed its life cycle as a consumer product, been collected, reprocessed, and molded into a new item. As one of our sources noted, the sustainability benefit of a PCR Cosmetic Bottle does not rely on the consumer's subsequent action, making it highly valuable for brands seeking immediate environmental impact. It represents a tangible step toward a circular economy by directly utilizing existing waste streams, thereby reducing the amount of waste sent to landfills and the subsequent production of virgin materials.

Deep Dive into PCR (Post-Consumer Recycled)

What is PCR Plastic?

PCR stands for Post-Consumer Recycled content or Post-Consumer Resin. It is arguably the most impactful material choice in the circular economy because it addresses the single biggest challenge: existing waste that would otherwise end up in landfills or pollute oceans.

Definition: PCR material is derived exclusively from products that have been used by end-consumers, collected via established recycling programs, and diverted from landfills or oceans. This includes everyday items like used plastic water bottles, yogurt containers, detergent jugs, and aluminum cans.

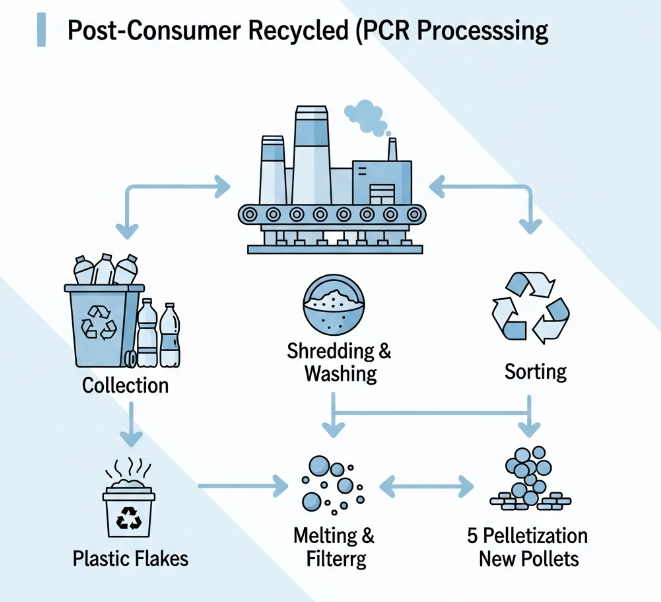

The Detailed PCR Process: The journey from a discarded bottle to a new PCR Cosmetic Bottle is complex, involving several critical steps, each requiring energy and quality control:

Collection and Transportation: Consumers place materials into municipal recycling bins. The efficiency of this starting point varies dramatically by region and collection infrastructure. The subsequent transportation to processing facilities also contributes a logistical cost and carbon footprint that must be managed.

Sorting & Baling (MRF Operations): At Material Recovery Facilities (MRFs), the mixed recyclables are meticulously sorted. This sorting process, which combines human labor with advanced optical sensors and air classification systems, is vital to separate materials based on polymer type and color. Accurate sorting is the first major hurdle to achieving high-quality PCR, after which the sorted materials are compressed into large, dense bales for efficient transport to a reprocessor.

Reprocessing, Cleaning, and Super-Cleaning: This is the most crucial, and often most expensive, stage. The bales are purchased, rigorously cleaned using hot washing—a process that must be sufficient to meet quality and potential food-contact standards. The material is then shredded into small flakes, melted at high temperatures, and filtered (extruded) through fine screens to remove any remaining non-plastic contaminants. For cosmetic and food-grade applications, a secondary "super-cleaning" decontamination step is often required to ensure chemical safety and purity.

Pelletization and Quality Verification: Finally, the molten, purified material is extruded through dies and cut into new, uniform resin pellets, now known as PCR. These pellets are subjected to final quality control checks for melt flow rate, density, and color consistency, becoming the verified raw input for a new generation of packaging.

PCR is an Umbrella Term for Source

Crucially, PCR is a measure of the material's origin, not its type. It is a declaration about the material’s history, certifying that it has already fulfilled its intended use by a consumer. A PCR material could therefore be any type of polymer:

PCR-PET: Post-Consumer Recycled Polyethylene Terephthalate, frequently used for clear bottles.

PCR-HDPE: Post-Consumer Recycled High-Density Polyethylene, known for its sturdiness and ideal for opaque containers.

PCR-PP: Post-Consumer Recycled Polypropylene, often used for caps, closures, and jars due to its rigidity and heat resistance.

When a brand uses a PCR Cosmetic Bottle, they are making an audited claim that the plastic used to create that specific bottle came from an item previously used and discarded by a consumer, directly diverting waste and strengthening the circular economy.

PCR in Cosmetic Applications

The use of PCR in the beauty sector is vast and growing, extending far beyond simple bottles due to continuous improvements in reprocessing technology and increased investment in high-quality separation techniques.

|

PCR Material Type |

Common Cosmetic Application |

Key Attribute |

|---|---|---|

|

PCR HDPE |

Shampoo/Conditioner Bottles, Body Wash Bottles |

High chemical resistance, opaque/milky finish, durable, highly abundant in waste streams. It's often the most accessible and cost-effective PCR option. |

|

PCR PET (rPET) |

Serums, Toners, Clear Bottles, Jars |

Better clarity than other PCR types, excellent oxygen barrier, preferred for transparent products where consumers need to see the formula. |

|

PCR PP |

Jars, Tubes, Caps, Closures |

Good heat resistance, ideal for thick creams, and increasingly used for intricate components like pumps and sprayers, closing the loop on more complex packaging parts. |

Leading brands are now successfully incorporating high percentages—from 30% to 100%—of PCR content into almost every packaging format, including flexible PCR Tubes and intricate PCR Compacts and Palettes, moving the entire industry toward more responsible material sourcing and challenging traditional reliance on virgin plastics.

The Powerful Environmental and Commercial Upsides

Choosing PCR packaging delivers tangible, measurable environmental metrics and a compelling brand narrative, far surpassing the benefits of materials that merely can be recycled.

1. Massive Reduction in Virgin Plastic Dependence and Resource Use: By utilizing consumer waste, PCR directly offsets the need for new, virgin plastic production, which is synthesized from non-renewable fossil fuels (oil and gas). Our analysis noted that PCR can cut virgin material consumption by up to 70% in certain applications. This translates directly into reducing the environmental costs associated with raw material extraction, including land disturbance, water usage in drilling, and the massive energy inputs required for polymerization, making a powerful statement about resource conservation and responsible sourcing.

2. Significant Energy Conservation and Lower Greenhouse Gas Emissions: The process of recycling existing plastic into PCR requires substantially less energy than manufacturing new polymer chains from scratch. Research consistently indicates that manufacturing PCR materials, particularly PCR-PET and PCR-HDPE, can use up to 79% less energy. This massive reduction in power consumption subsequently lowers the direct greenhouse gas emissions (GHG) associated with the brand's packaging production, dramatically improving the product's overall carbon footprint compared to an identical virgin plastic product.

3. Direct Waste Diversion and Global Pollution Mitigation: Every kilogram of certified PCR used is a kilogram that avoids becoming long-term waste in a landfill or, critically, becoming plastic pollution in oceans and waterways. This material choice acts as a financial incentive to improve global waste management systems. By investing in the PCR supply chain, brands are actively contributing to cleaner environments, reducing leaching from landfills, and mitigating the visual and ecological damage of plastic litter.

4. Enhanced Brand Reputation, Consumer Loyalty, and Regulatory Compliance: In the competitive beauty market, demonstrable environmental commitment is now a core value proposition. Using certified PCR Cosmetic Bottle materials, and communicating this transparency, builds trust and loyalty, attracting the rapidly expanding segment of eco-conscious shoppers. Furthermore, many jurisdictions are introducing mandates or taxes that incentivize the use of recycled content, making PCR a critical strategy for mitigating future regulatory costs and ensuring market access.

Deep Dive into rPET (Recycled PET)

What is rPET?

rPET stands for Recycled Polyethylene Terephthalate. Unlike PCR, rPET is defined purely by its chemical structure and composition.

Definition: rPET is the result of recycling PET plastic, which is the polymer designated by plastic resin code PET is valued for its exceptional mechanical strength, lightweight nature, and, most importantly for cosmetics, its strong barrier performance against moisture and gas permeation. This makes rPET the preferred material for clear, functional cosmetic packaging that must protect sensitive, high-value formulas like anti-aging serums and concentrated essences.

The Material Advantage: PET is recognized globally as one of the most widely recycled plastics, largely due to the immense volume generated by the bottled water and soft drink industries. This established infrastructure provides a relatively consistent and scalable feedstock stream. The material itself is chemically non-toxic and highly stable, allowing it to undergo rigorous super-cleaning processes, making rPET ideal for both food-contact and high-end cosmetic applications that demand regulatory compliance and safety assurance.

rPET Applications Beyond Cosmetics

The utility of rPET extends far beyond the beauty industry, contributing to massive, persistent demand that can sometimes strain supply for the cosmetic sector.

Food and Beverage Packaging: Due to its superior barrier properties and FDA/EFSA regulatory approval, rPET is extensively used for new bottled water, soft drinks, juices, and various food containers. This enormous, consistent demand serves as the primary driver and feedstock source for the rPET market.

Textiles and Fibers: Recycled PET is also a cornerstone of the sustainable textile industry. It is broken down and reformed into high-quality polyester fibers, commonly known as rPET fabric, which are used in everything from high-performance athletic apparel and footwear to durable carpets and upholstery, linking the plastic recycling industry to the fashion sector.

The Core Distinction – PCR vs. rPET

This section directly addresses the title: What is the difference between PCR Cosmetic Bottle and rPET Cosmetic Bottle?

The fundamental difference lies in the Scope of the term and the Source of the recycled material, which carries different environmental weight.

PCR is the Umbrella Term; rPET is the Specific Material

The clearest distinction, confirmed by our source analysis, is definitional and hierarchical:

PCR is an umbrella term that defines the material’s source (Post-Consumer waste). rPET is the specific material type (Recycled PET).

The terms are not mutually exclusive; they overlap. A bottle is correctly classified as both rPET and PCR. Therefore, a container made from recycled consumer waste PET is correctly labeled as a PCR-PET bottle, meaning it is a type of rPET bottle derived from a PCR source.

The Crucial "Pre-Consumer" vs. "Post-Consumer" Distinction

The true environmental and marketing power of PCR is only revealed when contrasting it with Pre-Consumer Recycled content (PIR).

Pre-Consumer Recycled (PIR/Pre-Consumer rPET): This material is recycled from clean, homogenous manufacturing waste generated before the product ever leaves the factory floor. While this is beneficial for reducing industrial scrap, it is generally considered a lower-impact sustainability claim because the material never entered the public waste stream and was often recycled internally anyway.

Post-Consumer Recycled (PCR): This material comes from products used and discarded by the public. This is the material that directly tackles landfill and pollution issues, and its retrieval is a greater logistical and technical challenge.

|

Feature |

PCR Cosmetic Bottle |

rPET Cosmetic Bottle (General Term) |

|---|---|---|

|

Definition |

Recycled plastic from consumer waste. |

Recycled plastic that is chemically PET. |

|

Source |

Mandatorily Post-Consumer. |

Can be Post-Consumer (PCR) OR Pre-Consumer (PIR). |

|

Scope |

Relates to the Source/Origin of the waste (Broad Polymer Coverage). |

Relates to the Chemical Type of the plastic (Specific to PET). |

|

"Green Story" |

Strongest narrative for circularity; directly reduces landfill waste and strengthens recycling infrastructure. |

Narrative strength depends on whether its source is certified PCR or PIR. |

When a brand simply uses the term rPET, it may unintentionally include PIR material, diluting the environmental story. The term PCR Cosmetic Bottle unequivocally guarantees the material’s origin from the public waste stream, satisfying the highest standards of circularity claims.

Why The Source Matters: The "Green Story" Power

The primary driver for the rise of PCR is its powerful, traceable, and impactful narrative, which resonates deeply with modern consumers. By prioritizing the PCR source:

Stronger Traceability and Anti-Greenwashing: PCR requires an auditable, verifiable chain of custody (often via third-party certification) to prove the material was diverted from the public waste stream. This commitment is essential for preventing accusations of greenwashing, as the brand can definitively show their contribution to global waste remediation.

Investment in Global Infrastructure: Demand for PCR material creates significant and necessary market incentives for investment in recycling programs globally. This demand drives improvements in collection, advanced sorting technology, and the intensive purification infrastructure—effectively funding the backbone of the true circular economy and increasing recycling rates in regions where they currently lag.

Practical Trade-Offs and Technical Hurdles

Choosing a sustainable material, whether a PCR-PET bottle or rPET from a mixed source, involves navigating technical, aesthetic, and economic trade-offs that impact product quality and brand perception.

Aesthetics, Clarity, and Quality Control

The recycling process inherently affects the material’s properties, forcing brands to balance sustainability claims with necessary product appearance and integrity.

Aesthetic Challenges (Clarity and Color Consistency):

The Tint Problem (Chemical Reason): While Virgin PET is perfectly clear, PCR PET (rPET) often exhibits a slight, unavoidable tint—ranging from grey or yellow to a milky hue. This discoloration is a result of mixed plastic colors in the feedstock (even trace amounts) and, crucially, the thermal degradation of the polymer during the repeated high-temperature reprocessing stages. This slight degradation changes the optical properties of the plastic.

Mitigation Strategies (Advanced Manufacturing): Brands can manage this challenge strategically. For opaque containers, they can use common opaque colors (especially prevalent with abundant PCR-HDPE) or incorporate highly concentrated color additives (like deep amber, forest green, or cobalt blue) to mask the base tint. Alternatively, manufacturers employ specialized blending techniques, such as using a multi-layer co-extrusion process where only the inner layer is 100% PCR, while the outer layer utilizes a virgin or low-PCR blend to maintain acceptable visual clarity.

Quality Control and Contamination Risk:

The complexity of dealing with highly variable post-consumer waste introduces significant quality control challenges that must be mitigated by advanced processing.

Variability in Feedstock (Melt Flow Index): The quality and molecular consistency of the source material fluctuate constantly, which impacts critical processing parameters like the melt flow index (MFI). This variability can affect the strength, consistency, and ultimate performance of the finished PCR Cosmetic Bottle during the blow-molding process, requiring constant, stringent quality testing.

Contamination Risk (Trace Residues): Trace amounts of previous contents, non-plastic residues (like metals from closures), and degradation products can survive standard cleaning. These contaminants can act as stress points, potentially leading to container defects such as microscopic "pinholes," structural weaknesses, or compromised barrier integrity. Only advanced systems employing high-efficiency sorting, aggressive hot washing, and multi-stage melt-filtering are capable of achieving the high purity required for premium cosmetic packaging.

Technical and Compatibility Challenges

Cosmetic packaging must protect the delicate formulation it contains throughout its specified shelf life, a requirement that becomes more complex with recycled materials.

Chemical Compatibility Testing (Accelerated Aging): Every unique cosmetic formula must be rigorously tested against the specific recycled polymer grade. Active ingredients can react differently with recycled polymers than with virgin plastics. Testing often involves "accelerated aging" studies, where packaged products are stored in high-temperature ovens for weeks to simulate months of real-world shelf life, checking for container failure, formula discoloration, or ingredient leaching.

Barrier Performance and Molecular Weight: The physical integrity of the bottle must maintain the same barrier performance against light, oxygen, and other external gases as its virgin counterpart. During mechanical recycling, the plastic's molecular chains can sometimes shorten, potentially leading to a slight reduction in molecular weight and reduced barrier properties. Any compromise in this barrier layer can lead to oxidation, degradation of active ingredients, and a reduced shelf life, which is a critical concern for high-value, air-sensitive serums packaged in rPET.

Cost and Supply Chain Dynamics

The economic landscape for PCR and rPET is volatile, marked by intense, cross-industry demand and complex processing requirements, impacting final cost.

|

Consideration |

PCR/rPET Reality (In-Depth) |

Analysis Context Resolution |

|---|---|---|

|

Processing Cost and Purity Grade |

The high operating cost—specifically the intensive sorting, advanced cleaning, and required super-cleaning steps—needed to achieve the required purity (especially for food-contact or clear PCR-PET) often makes the material more expensive than newly synthesized virgin plastic, despite the lower raw material input. |

Summary 2: Confirms that processing costs can be a challenge to affordability, particularly for high-grade PCR. |

|

Supply Constraints (Cross-Industry Competition): |

The global demand for high-quality, clear PCR-PET is fierce, driven simultaneously by the massive beverage sector, the textile industry, and the cosmetic sector. This overwhelming cross-industry competition significantly outpaces the available supply of reliable, high-purity PCR feedstock. Securing a reliable and consistent volume of this material remains the biggest hurdle for brands aiming for 100% PCR content and requires long-term supplier partnerships. |

Summary 2: Explicitly states that demand currently outpaces supply, creating a bottleneck that affects price stability and availability. |

|

Affordability and Regulatory Incentives: |

While high-purity clear rPET is costly, lower-grade or opaque PCR-HDPE, which is more abundant and easier to clean, can be a cost-effective solution. Furthermore, the overall cost equation shifts in regions where government regulations (like plastic taxes in Europe) or economic incentives heavily favor the use of certified recycled content, making PCR adoption a financial advantage over paying virgin plastic taxes. |

Summary 3: Suggests affordability is possible, which can be true for specific, less demanding PCR grades or highly mature, incentivized markets. |

Making the Informed Choice for Your Cosmetic Brand

Choosing between different grades of recycled plastic requires aligning material goals with brand philosophy, budget, and desired aesthetics, all while ensuring product safety.

A Comparative Summary Table

|

Feature |

PCR (Post-Consumer Recycled) |

rPET (Recycled PET) |

|---|---|---|

|

Focus |

Source (Where the plastic came from—waste diversion) |

Material Type (The chemical structure: PET) |

|

Material Types |

PET, HDPE, PP, LDPE, etc. (Source-defined) |

Only PET (Resin Code #1) |

|

Best Story |

The strongest claim for supporting the circular economy and addressing landfill waste. |

Strong, but requires clarification on source (PIR vs. PCR) to ensure maximum credibility and consumer trust. |

|

Clarity |

Often has lower clarity, inherent color variability, and is harder to achieve 100% clear due to processing. |

Clarity varies widely; high-clarity rPET often includes PIR or virgin blends to meet stringent aesthetic demands. |

|

Key Keyword |

PCR Cosmetic Bottle (Focuses on ethical source and waste reduction) |

Sustainable Cosmetic Packaging (General term, needs qualification by the PCR percentage) |

Best Practices for Brands

Prioritize Certified and Audited PCR Content: If your brand’s core story is rooted in true waste reduction, it is imperative to demand certified PCR Cosmetic Bottle materials (PCR-PET, PCR-HDPE, etc.) with auditable supply chains. Certifications ensure traceability and prevent unintentional reliance on lower-impact Pre-Consumer (PIR) waste, protecting your brand's integrity.

Invest Heavily in Rigorous Testing and Quality Assurance: Due to the material's inherent variability, comprehensive compatibility, stability, and leak testing are crucial. This safeguards the delicate formulation, prevents costly product recalls, and protects the brand's long-term reputation—an essential step often overlooked in the rush to sustainability.

Strategic Aesthetic Management: Brands must consciously decide whether to embrace the slight tint and natural inconsistencies of 100% PCR as an "authenticity aesthetic" (demonstrating recycled content) or manage clarity demands by strategically using blends or moving to opaque PCR-HDPE bottles where color matching is simpler and more reliable.

Educate the Consumer with Radical Transparency: Move beyond vague "eco-friendly" claims. Use clear, specific, and precise labeling that not only says "rPET" or "PCR Cosmetic Bottle" but specifies the material and the exact percentage of certified recycled content. This level of detail builds essential trust and helps consumers understand the measurable impact of their purchase on the circular economy.

The difference between a PCR Cosmetic Bottle and an rPET Cosmetic Bottle is one of scope and origin. The term rPET is a technical description of the plastic's chemical identity, while PCR is the gold standard for defining its ethical source.

In the race for sustainable cosmetic packaging—whether adopting emerging alternatives like the Straw Cosmetic Bottle or maximizing material circularity with existing plastics—the industry must continue to champion the use of Post-Consumer Recycled Resin. By demanding high percentages of PCR-PET, PCR-HDPE, and PCR-PP, brands reduce their reliance on virgin materials, lower their energy consumption, and actively fund the recycling infrastructure that our planet desperately needs. This commitment requires navigating significant technical hurdles related to aesthetics, quality, and supply, but the environmental and commercial rewards—enhanced brand equity, reduced regulatory risk, and tangible waste reduction—make the effort undeniably worthwhile for producing a truly Environmental Cosmetic Bottle.

The future of beauty is not just about luxurious formulations, but about circular responsibility—a commitment that starts with making the right choice between a PCR Cosmetic Bottle and simply an rPET container. By understanding this distinction, brands can truly deliver on their promise of eco-friendly beauty.

English

English Español

Español